|

Rainbow Magnet Ltd.

|

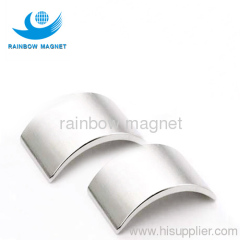

sintered ARC NdFeB Magnets. Permanent neodymium arc magnet.

| Price: | 0.01~50.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

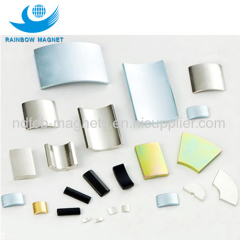

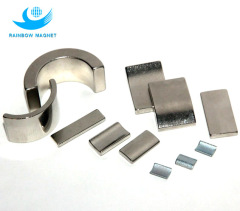

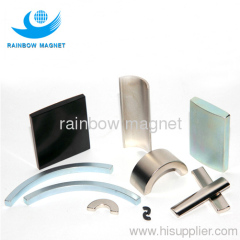

1) Arc with difference coating:black epoxy,blue Zn coating,Ni coating

2) difference radian and size according customer demand

3) various grade

Neodymium Iron Boron magnet is a type of rare-earth permanent magnet. It is made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure. This material is currently the strongest type of permanent magnetin the world.

There are two kinds of magnets: Sintered NdFeB magnet and bonded NdFeB magnet.

NdFeB has a very high energy product and coercivity, can pick up 660 times of own weight of heavy objects.

The advantage is high cost-effective, with good mechanical properties, easy cutting; according customer's demand to manufacture in a wide range of shapes, sizes and grades.

Also have high Br,high Hcj,high (BH)max,and high stability become the important material of the world.

The shortcoming is the low of the Curie temperature and the temperature characteristics, easy to rust, oxidation, Sintered NdFeB's surface is usually required for plating such as zinc, nickel, silver, gold, etc., can also be done phosphorus treatment or spray epoxy resin to slow down the oxidation rate.

Nd-Fe-B permanent magnet with its excellent performance, abundant raw material and reasonable price is to be rapid development and wide application.

Also becoming increasingly popular across a wide range of novelty products for markets.

APPLICATION:

instrumentation,

electro-acoustic motor,

magnetic magnetization device

micro motors,

electronic industry,

automobile industry,

petrochemicals,

nuclear magnetic resonance device,

sound device magnetic suspension system,

magnetic transmission machine

magneto therapy equipment

high performance motors,

brushless DC motors,

generators,

magnetic separation,

magnetic resonance imaging,

sensors

loudspeakers

headphones,

hearing aids,

voice coil motors,

magnetic vibrators,

vibrating motors,

permanent magnet motors,

magnetic thrust axis,

magnetic machinery,

magnetic spring,

magnetic vibration device

magnetic connection,

magnetic drive,

Permanent magnet crane

electromagnetic pumps,

magnetic separators

MRI

magnetic machine

Attached picture show the Arc NdFeB Magnets with difference coating:

Attached picture show the Arc NdFeB Magnets with difference coating:

Arc NdFeB Magnet in EH grade's properties:

Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Maximum Operating Temperature | ||||

Br | Hcb | Hcj | (BH)max | Tw | |||||

T | KGS | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | |

N28EH | 1.04-1.08 | 10.4-10.8 | 780-812 | 9.8-10.2 | ≥2388 | ≥30 | 207-223 | 26-28 | ≤200 |

N30EH | 1.08-1.12 | 10.8-11.2 | 804-844 | 10.1-10.6 | ≥2388 | ≥30 | 223-239 | 28-30 | ≤200 |

N33EH | 1.14-1.17 | 11.4-11.7 | 820-876 | 10.3-11.0 | ≥2388 | ≥30 | 247-263 | 31-33 | ≤200 |

N35EH | 1.17-1.21 | 11.7-12.1 | 860-907 | 10.8-11.4 | ≥2388 | ≥30 | 263-279 | 33-35 | ≤200 |

N38EH | 1.22-1.26 | 12.2-12.6 | 860-907 | 10.8-11.4 | ≥2388 | ≥30 | 287-303 | 36-38 | ≤200 |

Arc NdFeB magnet demagnetization curve ofEH grade in difference temperature:

NdFeB,AlNiCo,SmCo,magnetic composition and properties compare as follows:

Type | composition | Magneticproperties | ||||

Br/T | Hc /(Ka/m) | (BH)m/ (kJ/m3) | Tc/℃ | Density g/cm-3 | ||

Sinter NdFeB | Nd13.5(Fe,M)bananceB6.1-7.0 | 1.1-1.4 | 800-2400 | 240-400 | 310-510 | 7.4-7.6 |

Bonded NdFeB | Nd4-13(Fe,M)bananceB6-12 | 0.6-1.1 | 800-2100 | 56-160 | 310 | 5.3-6.0 |

AlNiCo5 | 8%-12%Al,15%-22%Ni 5%-24%Co,3%-6%Cu. BalanceFe | 0.7-1.32 | 40-60 | 9-56 | 890 | 7.3 |

AlNiCo8 | 7%-8%Al,14%-15%Ni 34%-36%Co,5%-8%Ti, 3%-4%Cu,BalanceFe | 0.3-0.44 | 250-350 | 25-36 | 450 | 7.3 |

1:5,SmCo | 62%-63%Co,38%-37%Sm | 0.9-1.0 | 1100-1540 | 117-179 | 720 | 8.1 |

2:17,SmCo | Sm(Co0.69Fe0.2Cu0.1Zr0.01)7.2 | 1.0-1.3 | 500-600 | 230-240 | 800 | 8.2 |

Bondedsmco | Sm(Co0.67Fe0.22Cu0.1Zr0.07Ti0.01)7.1 | 1.0-1.07 | 800-1400 | 160-204 | 810 | 7.4 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Ndfeb Arc Magnets

Arc Ndfeb Magnet

Sintered Ndfeb Permanent Magnet

Arc Magnet

Sintered Ndfeb Ring Magnets

Permanent Ndfeb Magnets

More>>