|

Rainbow Magnet Ltd.

|

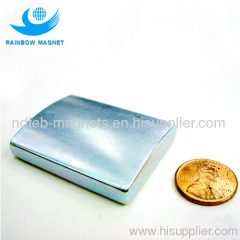

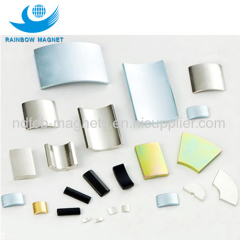

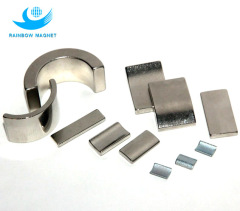

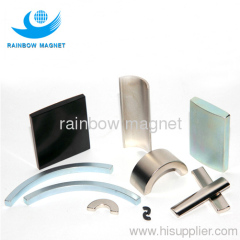

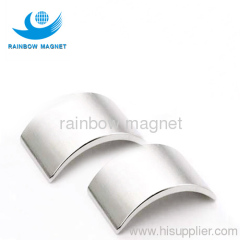

vibrating motors. Arc magnet. NdFeB Segment. motor magnet

| Price: | 0.01~100.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Powerful magnetic force

2. high corrosion resistance

3. excellent performance

A neodymium magnet is a type of rare-earth permanent magnet. It is made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure. This material is currently the strongest type of permanent magnet in the world.

This Sintered NdFeB magnet is coated with Titanium (Ti), the magnetized through the axial direction.

Note: The above mentioned data of magnetic parameters and physical are given at 20℃±2℃

The main physical properties of sintered NdFeB segment

Nd-Fe-B permanent magnet is manufactured in a wide range of shapes, sizes and grades according customer's demand.

NdFeB has a very high energy product and coercivity, can pick up 660 times of own weight of heavy objects.

The advantage is high cost-effective, with good mechanical properties, easy cutting; according customer's demand to manufacture in a wide range of shapes, sizes and grades.

The shortcoming is easy to rust, oxidation, so the Sintered NdFeB's surface is usually required for plating such as zinc, nickel, silver, gold, etc., can also be done phosphorus treatment or spray epoxy resin to slow down the oxidation rate.

The magnetic field stability is important, the higher the coercivity of the permanent magnet alloy in other conditions as well as by the smaller the losses caused by external magnetic interference

The M grade and its details properties, pls see follow table.

Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Maximum Operating Temperature | ||||

Br | Hcb | Hcj | (BH)max | Tw | |||||

T | KGS | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | |

N35M | 1.17-1.21 | 11.7-12.1 | 892-915 | 11.2-11.5 | ≥1114 | ≥14 | 263-279 | 33-35 | ≤100 |

N38M | 1.22-1.26 | 12.2-12.6 | 907-931 | 11.4-11.7 | ≥1114 | ≥14 | 287-303 | 36-38 | ≤100 |

N40M | 1.26-1.29 | 12.6-12.9 | 907-947 | 11.4-11.9 | ≥1114 | ≥14 | 303-318 | 38-40 | ≤100 |

N42M | 1.30-1.33 | 13.0-13.3 | 907-947 | 11.4-11.9 | ≥1114 | ≥14 | 318-334 | 40-42 | ≤100 |

N45M | 1.33-1.37 | 13.3-13.7 | 907-955 | 11.4-12.0 | ≥1114 | ≥14 | 334-358 | 42-45 | ≤100 |

N48M | 1.36-1.42 | 13.6-14.2 | 907-955 | 11.4-12.0 | ≥1114 | ≥14 | 358-382 | 45-48 | ≤100 |

The main physical properties of sintered NdFeB segment

magnetic properties | Parameters |

Density /g.cm3 Vickers Hardness HV Resistivity /υΩ.cm Compressive strength/N.mm-2 Coefficient of Thermal Expansion (C⊥)/K-1 Coefficient of Thermal Expansion (C∥) /K-1 | 7.45 570 150 780 -4.8X10-6 -3.4X10-6 |

APPLICATION:

instrumentation,

electro-acoustic motor,

magnetic magnetization device

micro motors,

electronic industry,

automobile industry,

petrochemicals,

nuclear magnetic resonance device,

sound device magnetic suspension system,

magnetic transmission machine

magneto therapy equipment

high performance motors,

brushless DC motors,

generators,

magnetic separation,

magnetic resonance imaging,

sensors

Neo segment, brushless DC motors

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Ndfeb Segment Magnet

Ndfeb Magnet Segment

Arc Ndfeb Magnet

Arc Motor Ferrite Magnet

Segment Magnet

Arc Magnet

More>>