|

Rainbow Magnet Ltd.

|

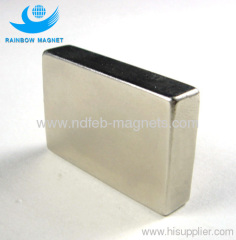

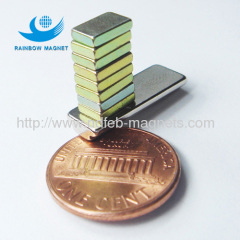

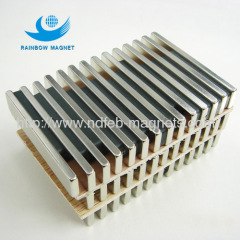

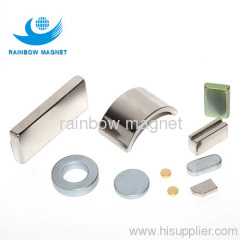

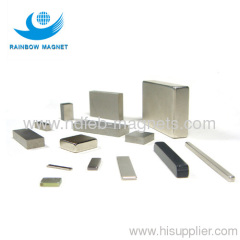

permanent magnet slice

| Price: | 0.1~10.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The magnet made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure.

According the max working temperature, we can divide Sintered magnet to 7 grades, N grade is for 80 ℃,grade M is for 100℃,grade H is for 120℃,grade SH is for 120℃,grade UH is for 150℃ and grade EH is for 200℃,you according your demand to choose the grade which you need.

Mostly of rare earth permanent magnet always work do not at room temperature or under vacuum, in order to keep the accuracy of shape size and avoid the Corrosion and oxidation, we must make the coating on the surface.

Sometime, the customers have high demand of NdFeB anti-corrosion, antioxidant, we can design the magnet,add some elements, such as: niobium, vanadium, cobalt and other metal to replace part of the iron to catch the customer requirements of the acid and alkali resistant,antioxidant level, however, because of special material, we need MOQ for it.

How to judge the Permanent magnet material properties advantages and disadvantages of standard?

You can see 3 terms:

1)the magnet -crystalline anisotropy,

2)the magnetization strong

3)the Curie temperature.

salt spray test results for coating

Commonly type of coating | Coating thickness(um) | Neutral salt spray test | ||||

dark Ni | Cu | Shine Ni | Total | |||

Single-layer Ni | 25 | 25 | 24h | normal | ||

Double-layer Ni | 12 | 10 | 25 | 72h | better | |

Dark Ni-Cu–shine Ni | 6.25 | 8.75 | 10 | 25 | 120h | excellent |

The main physical properties for permanent magnet slice:

magnetic properties | Parameters |

Density /g.cm3 Vickers Hardness HV Resistivity /υΩ.cm Compressive strength/N.mm-2 Coefficient of Thermal Expansion (C⊥)/K-1 Coefficient of Thermal Expansion (C∥) /K-1 | 7.45 570 150 780 -4.8X10-6 -3.4X10-6 |

the magnetic properties of rare earth magnet:

compare NdFeB and SmCo

item | Js/T | (BH)m /KJ.m-3 | HA /MA.m-1 | Tc/℃ | RE/TM | TM |

Nd2Fe14B | 1.61 | 528 | 6 | 310 | 0.117 | Fe |

SmCo5 | 1.15 | 248 | 32 | 740 | 0.166 | Co |

Sm2Co17 | 1.56 | 480 | 8 | 890 | 0.105 | Co |

attached pic show permanent magnet slice with black Ni coating

welcome to enquiry the permanent magnet slice.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Permanent Magnet

Ring Permanent Magnet

Ndfeb Permanent Magnet

Smco Permanent Magnet

Dc Permanent Magnet

Permanent Magnet Motor

More>>