|

Rainbow Magnet Ltd.

|

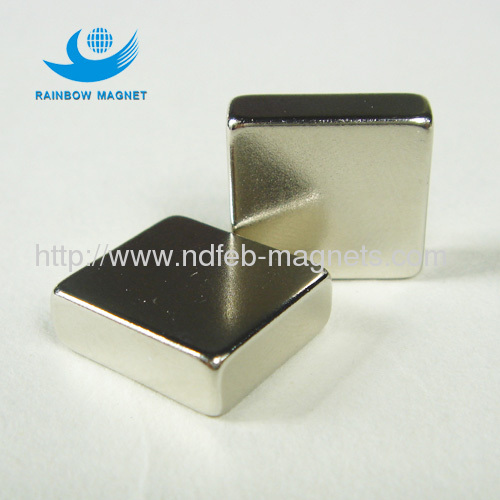

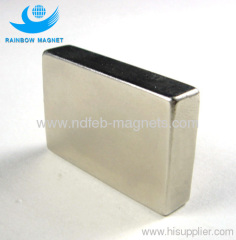

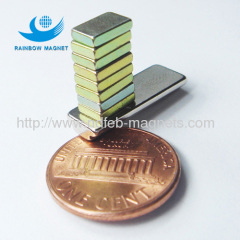

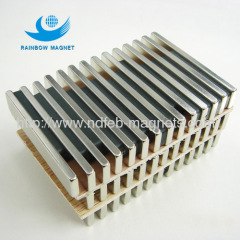

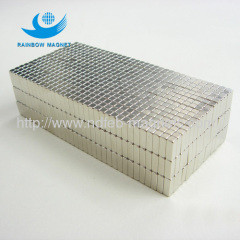

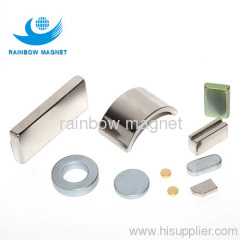

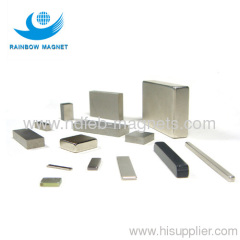

Neodymium Iron Boron square magnet

| Price: | 0.1~8.0 EUR |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

NdFeB has a very high energy product and coercivity, can pick up 660 times of own weight of heavy objects.

Neodymium Iron Boron square magnet is manufactured in a wide range of shapes, sizes and grades according customer's demand.

Neodymium Iron Boron square magnet's advantage is high cost-effective, with good mechanical properties, easy cutting; according customer's demand to manufacture in a wide range of shapes, sizes and grades.

The shortcoming is easy to rust, oxidation, so the Sintered NdFeB's surface is usually required for plating such as zinc, nickel, copper,silver, gold, etc., can also be done phosphorus treatment or spray epoxy resin to slow down the oxidation rate.

the stability of the time: the place of limitation caused by room temperature for a long time, the coercive force of it and the materials used by the permanent magnet and the magnet size ratio, the higher the coercivity, size ratio, itmore stable. During use to maintain the stability of the exchange forced demagnetization method can obtain good results.

Pic shows the magnet with NiCuNi coating and the grade is UH,it means max working temperature is 180 degree.

Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Maximum Operating Temperature | ||||

Br | Hcb | Hcj | (BH)max | Tw | |||||

T | KGS | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | |

N28UH | 1.04-1.08 | 10.4-10.8 | 780-812 | 9.8-10.2 | ≥1990 | ≥25 | 207-223 | 26-28 | ≤180 |

N30UH | 1.08-1.12 | 10.8-11.2 | 804-844 | 10.1-10.6 | ≥1990 | ≥25 | 223-239 | 28-30 | ≤180 |

N33UH | 1.14-1.17 | 11.4-11.7 | 820-876 | 10.3-11.0 | ≥1990 | ≥25 | 247-263 | 31-33 | ≤180 |

N35UH | 1.17-1.21 | 11.7-12.1 | 860-907 | 10.8-11.4 | ≥1990 | ≥25 | 263-279 | 33-35 | ≤180 |

N38UH | 1.22-1.26 | 12.2-12.6 | 860-907 | 10.8-11.4 | ≥1990 | ≥25 | 287-303 | 36-38 | ≤180 |

N40UH | 1.26-1.29 | 12.6-12.9 | 860-907 | 10.8-11.4 | ≥1990 | ≥25 | 289-303 | 38-40 | ≤180 |

Note: The above mentioned data of magnetic parameters and physical are given at 20℃±2℃

The use of transport: cars, electric cars.

Lubricating device, window motor, pump motor, debris collection, seat adjustment motor, antenna lift motor, heating adjustment motor, wiper electrical, coolant fan motor, starter motor, ignition system, headlight door motor, liquid level displays, ultra-high-speed control, speedometer, windshield wash pump, sun motor, automatic temperature control, speakers, go to fog the motor, door lock motor, tailgate motor.

Neo magnet with square shape and high Hci

APPLICATION:

automobile industry,

The main physical properties of Neodymium Iron Boron square magnet

magnetic properties | Parameters |

Density /g.cm3 Vickers Hardness HV Resistivity /υΩ.cm Compressive strength/N.mm-2 Coefficient of Thermal Expansion (C⊥)/K-1 Coefficient of Thermal Expansion (C∥) /K-1 | 7.45 570 150 780 -4.8X10-6 -3.4X10-6 |

The use of transport: cars, electric cars.

Lubricating device, window motor, pump motor, debris collection, seat adjustment motor, antenna lift motor, heating adjustment motor, wiper electrical, coolant fan motor, starter motor, ignition system, headlight door motor, liquid level displays, ultra-high-speed control, speedometer, windshield wash pump, sun motor, automatic temperature control, speakers, go to fog the motor, door lock motor, tailgate motor.

Neo magnet with square shape and high Hci

APPLICATION:

automobile industry,

petrochemicals,

nuclear magnetic resonance device,

sound device magnetic suspension system,

magnetic transmission machine

magneto therapy equipment

high performance motors,

loudspeakers

headphones,

hearing aids,

voice coil motors,

magnetic vibrators,

vibrating motors,

permanent magnet motors,

Permanent magnet crane

electromagnetic pumps,

magnetic separators

MRI

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Neodymium Iron Boron Magnet

Sintered Neodymium Iron Boron

Neodymium Iron Boron

Iron Boron

Neodymium Magnet

Sintered Neodymium Magnet

More>>