|

Rainbow Magnet Ltd.

|

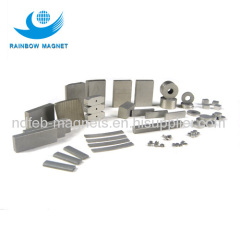

smco segment motor permanent magnet

| Price: | 0.01~10.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Various kind of smco magnet

2.Best quality and good price

3.High quality

Arc samarium cobalt Sm2Co17 magnet:

Samarium cobalt magnets are composed of samarium, cobalt and iron. These rare earth magnets are extremely strong for their small size, metallic in appearance and found in simple shapes such as rings, blocks and discs.

According the composition, we divide two of SMCO: Sm2CO17 and SmCo5

Sm2Co17:

Feature:

Metal samarium, cobalt, copper, iron, zirconium, according percentage tomelting, grinding, profiling, sintering, aging, and make of various grades, shapes and sizes.

The (BH)max between 20-32, the maximum operating temperature can bereached 350 °C, the 2:17 has a low temperature coefficient (-0.02% / ℃) and good corrosion resistance, magnetic properties ismore than NdFeB magnets when in high working temperatures,

Sm2co17: not only has a high intrinsic saturation magnetic induction, but also good anti-oxidation.

The Curie temperature is high to 840-870 degrees, higher than Smco5.

The disadvantage is that the process is complex with high costs.

Applications

aerospace fields,

military fields,

high temperature motor,

automotive sensors,

variety of magnetic drive,

magnetic drive pump,

microwave devices.

Computer disc drives

Sensors

Radar

Traveling wave tubes

Satellite systems

Motors where temporary stability is vital

Arc samarium cobalt Sm2Co17 magnet

Arc samarium cobalt Sm2Co17 magnet

Type | composition | Magneticproperties | ||||

Br/T | Hc /(Ka/m) | (BH)m/ (kJ/m3) | Tc/℃ | Density g/cm-3 | ||

1:5,SmCo | 62%-63%Co,38%-37%Sm | 0.9-1.0 | 1100-1540 | 117-179 | 720 | 8.1 |

2:17,SmCo | Sm(Co0.69Fe0.2Cu0.1Zr0.01)7.2 | 1.0-1.3 | 500-600 | 230-240 | 800 | 8.2 |

AlNiCo5 | 8%-12%Al,15%-22%Ni 5%-24%Co,3%-6%Cu. BalanceFe | 0.7-1.32 | 40-60 | 9-56 | 890 | 7.3 |

AlNiCo8 | 7%-8%Al,14%-15%Ni 34%-36%Co,5%-8%Ti, 3%-4%Cu,BalanceFe | 0.3-0.44 | 250-350 | 25-36 | 450 | 7.3 |

SinterNdFeB | Nd13.5(Fe,M)bananceB6.1-7.0 | 1.1-1.4 | 800-2400 | 240-400 | 310-510 | 7.4-7.6 |

Bonded | Nd4-13(Fe,M)bananceB6-12 | 0.6-1.1 | 800-2100 | 56-160 | 310 | 5.3-6.0 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Smco Permanent Magnet

Permanent Magnet Motor

Permanent Magnet Dc Motor

Brushless Permanent Magnet Motor

SmCo Magnet

Segment Magnet

More>>