|

Rainbow Magnet Ltd.

|

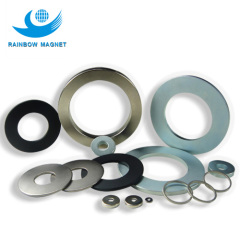

Permanent neodymium Iron Boron ring magnets black epoxy coat

| Price: | 0.1~10.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1) Black epoxy coating neodymium magnet rings.

2) huge size up to 220mm diameter

3) excellent performance and high corrosion resistance

permanent neodymium Iron Boron ring magnets is made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure. This material is currently the strongest type of permanent magnet in the world.

The ring manget is one regular and popular shape of sintered neodymium magnet.

The neodymium disc magnet is mainly usedin auto speakers.

Mostly of rare earth permanent magnet always work do not at room temperature or under vacuum, in order to keep the accuracy of shape size and avoid the Corrosion and oxidation, we must make the coating on the surface.

attached picture show black epoxy coatingring magnet

attached picture show black epoxy coatingring magnet

The main physical properties of sintered NdFeB black epoxy coatingring magnet:

magnetic properties | Parameters |

Density /g.cm3 VickersHardness HV Resistivity /υΩ.cm Compressivestrength/N.mm-2 Coefficient of ThermalExpansion (C⊥)/K-1 Coefficient of ThermalExpansion (C∥) /K-1 | 7.45 570 150 780 -4.8X10-6 -3.4X10-6 |

The advantage of magnet is high cost-effective, with good mechanical properties, easy cutting; according customer's demand to manufacture in a wide range of shapes, sizes and grades.

Also have high Br,high Hcj,high (BH)max,and high stability become the important material of the world.

The shortcoming is the low of the Curie temperature and the temperature characteristics, easy to rust, oxidation, Sintered NdFeB's surface is usually required for plating such as zinc, nickel, silver, gold, etc., can also be done phosphorus treatment or spray epoxy resin to slow down the oxidation rate.

Nd-Fe-B permanent magnet with its excellent performance, abundant raw material and reasonable price is to be rapid development and wide application.

Also becoming increasingly popular across a wide range of novelty products for markets.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Neodymium Iron Boron Magnet

Sintered Neodymium Iron Boron

Neodymium Iron Boron

Magnets Neodymium

Epoxy Magnets

Iron Boron

More>>