|

Rainbow Magnet Ltd.

|

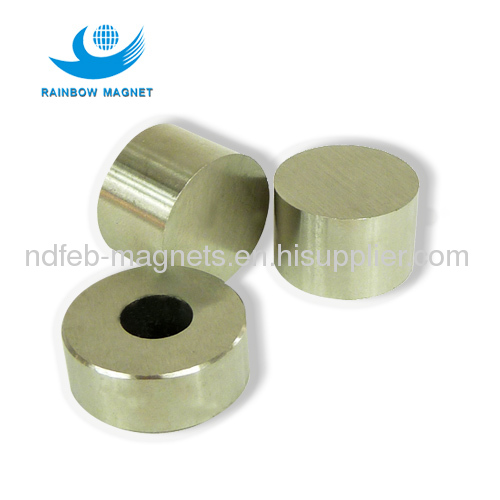

cylinder permanent magnetic alloy of CAST AlNiCo magnets

| Price: | 0.01~50.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Cast aluminum nickel and cobalt with low temperature coefficient, operating temperature up to 550 degrees Celsius.

permanent

permanent permanent magnetic alloy of CAST AlNiCo magnets

permanent magnetic alloy of CAST AlNiCo magnets' products are widely used in various instruments and other applications.

Cast aluminum nickel and cobalt resistant to heat and moisture, not easy to oxidized, and working stability is the best,it is graet for high heat applications

permanent magnetic alloy of CAST AlNiCo magnets are made from aluminum, nickel, cobalt, copper, iron, titanium and other element.

Casting process can be processed production into different sizes and shapes;

The advantages of the Alnico magnet remanence (up to 1.33T), low temperature coefficient. The temperature coefficient of -0.02% / ° C, while the maximum operating temperature up to about 550 ℃.

Shortcoming: the coercivity is very low (typically less than 140kA / m), demagnetization curve is nonlinear. Alnico magnets easily magnetized, also easy to demagnetization.

Applications:

auto parts,

instrumentation,

electro-acoustic

aerospace military

Water meter

Sensors

Electron tubes

Traveling wave tubes

Radar

Holding magnets

Clutches and bearings

Motors

Relays

Cow magnet

Educational products

other fields.

Cast AlNiCo magnetic energy parameters' difference with other NdFeB magnets and SmCo magnets:

demagnetization curve for permanent magnetic alloy of AlNiCo magnets

Type | composition | Magnetic properties | ||||

Br/T | Hc /(Ka/m) | (BH)m/ (kJ/m3) | Tc/℃ | Density g/cm-3 | ||

AlNiCo 5 | 8%-12%Al,15%-22%Ni 5%-24%Co,3%-6%Cu. Balance Fe | 0.7-1.32 | 40-60 | 9-56 | 890 | 7.3 |

AlNiCo8 | 7%-8%Al,14%-15%Ni 34%-36%Co,5%-8%Ti, 3%-4%Cu,Balance Fe | 0.3-0.44 | 250-350 | 25-36 | 450 | 7.3 |

1:5,SmCo | 62%-63%Co,38%-37%Sm | 0.9-1.0 | 1100-1540 | 117-179 | 720 | 8.1 |

2:17,SmCo | Sm(Co0.69Fe0.2Cu0.1Zr0.01)7.2 | 1.0-1.3 | 500-600 | 230-240 | 800 | 8.2 |

Bonded smco | Sm(Co0.67Fe0.22Cu0.1Zr0.07Ti0.01)7.1 | 1.0-1.07 | 800-1400 | 160-204 | 810 | 7.4 |

Sinter NdFeB | Nd13.5(Fe,M)bananceB6.1-7.0 | 1.1-1.4 | 800-2400 | 240-400 | 310-510 | 7.4-7.6 |

Bonded NdFeB | Nd4-13(Fe,M)bananceB6-12 | 0.6-1.1 | 800-2100 | 56-160 | 310 | 5.3-6.0 |

demagnetization curve for permanent magnetic alloy of AlNiCo magnets

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Permanent Magnetic Cylinder

Magnets Alnico

Cast AlNICO

Alnico Permanent Magnet

Permanent Alnico Magnet

Bonded Alnico Magnets

More>>